TMT Bar Mills

custom html1

Get your brochures

TMT Bar Mills

TMT: 8 to 40mm

WIRE ROD : 5.5 to 10mm

Mill Size : 10,000 to 50,000 TPA

50,000 to 200,000 TPA

200,000 to 600,000 TPA

UGI designed TMT Bar Mills has a varied range of production & each mill is designed & customised as per the customer requirement. We engineered the TMT plant in accordance with the desired Tonnage and product mix, size of Input material and degree of automation.

Our technical collaboration with SEAD Steel Technologies is for SLIT Rolling for production of TMT Mills beyond 200,000 TPA capacity. This collaboration for technological enhancement, engineering, process knowhow, operational support required for the mill.

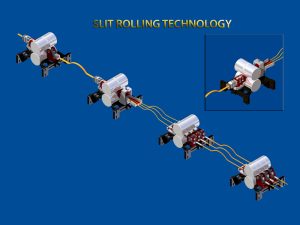

SLIT Technology

UGI Engineering is manufacturing bar & rod mill upto 500,000 TPA mill with Slit Rolling Technology. High production is achieved using “Slit Technology” which is proven technology in European countries .

FLOW PROCESS FOR SLIT ROLLING IN BAR MILL

-

BILLET

(130x130x600mm/12000mm-780 kg/1560 kg)

-

Billet receiving and charging

-

Billet reheating in the furnance (Pusher Type)

-

Pinch roller discharge from the furnace

-

Hot billet transfer by inlet roller table

-

Toggle shear with pinch roll

-

3 high roughing mill

(4 stand H-V configuration in future)

-

Intermediate mill (6 stands H-V configuration)

-

Flying crop shear

-

Finishing mill (6 stands H-V configuration)

Ind. Slitting mill stand

-

T.M.T.

-

Cut-to-length flying shear

-

Cooling bed

-

Cold bar shear

-

Bar bundling and counting

-

Typing

-

BUNDLES WEIGHING AND DESPATCHING