Mill Shears & Saws

Mill Shears & Saws

UGI Mill Shears & Saw Machine has made from EN-8 Steel fabricated stress relived body construction with control panel, starter, Automatic Operating System & Centralize Oil Lubrication System . UGI Engineering offers a full line of hot and cold shears necessary in a Wire Rod Mill , TMT Mill , Section Mill & Strip Mill for a wide variety of requirements, such as head/ tail cropping , dividing, sampling or scrapping, cutting-to-length. Sawing units are available for rails, medium-large sections, large bars, and special steel grades, where sawing is preferred over shearing.

| FLYING SHEAR | Start & Stop type/ Cut-to Length To cut finished bars /Angles / flats at the desiredlength Max PCD -1000mm, Max. Stock size -32mm |

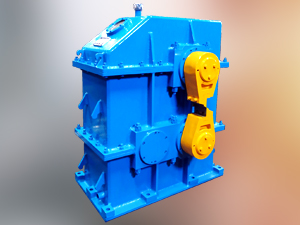

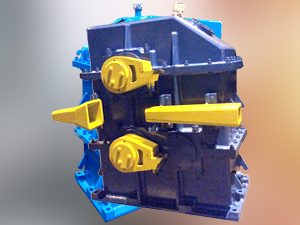

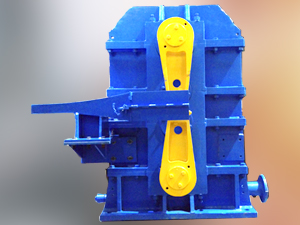

| CROP&COBBLE SHEAR | Start & Stop type/Clutch type/Crank type To cut front and tail end, cobble up Bars Max PCD – 1000mm, Max. Stock size – 100mm |

| COLD SHEAR | Mechanical / Hydraulically operated To cut finish product TMT/Structural sections Max. capacity – 500 MT |

| ROTARY SHEAR | Fixed & Swivelling To cut front and tail end , cut-to-length Max. PCD – 610mm, Max. Stock size – 50mm |

| BILLET SHEAR | To cut upto 150 x 150mm billet |

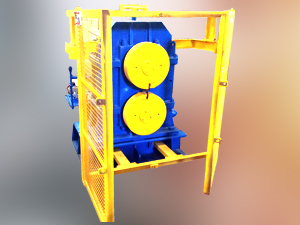

| CONTINUOUS SHEAR | For cutting 8,10 and 12 mm |

| HOT SAW | For cutting Section/Structurals/Rounds/Square |

CROP & COBBLE SHEAR

CROP & COBBLE SHEAR

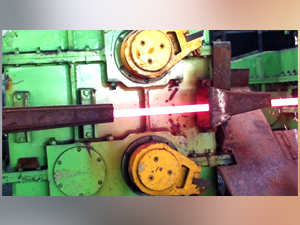

CROP & COBBLE SHEAR IN OPERATION

CRANK SHEAR

CONTINUOUS SHEAR

CONTINUOUS SHEAR

FLYING SHEAR

ROTARY SHEAR

HOT SAW