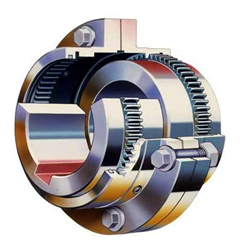

Gear Coupling

Gear Coupling

The advantages of using Geared Coupling on all directly connected machinery is now recognized and appreciated by engineers and operating men. Gear couplings are intended to compensate for the usual and unavoidable errors in alignment and should allow free lateral flowto the connected shafts. Even when favourable conditions permit perfect alignment to the two Shafts, there is no assurance they will remain so, the vibrations, the sinking of foundation, wear of bearings and inaccuracies in machining are all common enemies to the safe and efficient operation of connected machinery.

Misalignment of machines connected by rigid couplings not only causes excessive wear of couplings and machine parts but also increase power consumption. When two out of line shafts are connected rigidly, severe bending stresses are set up in each shaft. For each revolution, the shaft passes through a complete cycle of tension and compression stresses and would be likely to fatigue the shaft material and considerable heat and damage the whole mechanism.

When transmitting torque you need a perfect selection and correct type of coupling to achieve the maximum optimum efficiency and dependability. Our designed gear couplings with Triple Crowned barrel shaped tooth coupling are the solution the your problems. Built to last longer, protect your equipment and save your money, Universal Gear Couplings are right for a whole world of applications.

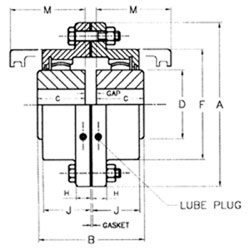

Curved Tooth Gear Coupling

|

Size |

HP |

Torque |

Speed |

Bores |

A |

C |

D |

F |

H |

J |

M |

GAP |

Weight |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Flex |

Min |

Pilot |

|||||||||||||

|

1001 |

14.5 |

105 |

6300 |

45 |

20 |

15 |

170 |

55 |

65 |

110 |

17 |

49 |

65 |

5 |

10 |

|

1002 |

31.5 |

225 |

5000 |

60 |

30 |

20 |

185 |

70 |

85 |

125 |

17 |

62 |

80 |

5 |

15 |

|

1003 |

67 |

485 |

4000 |

75 |

40 |

20 |

220 |

85 |

105 |

150 |

20 |

78 |

105 |

5 |

26 |

|

1004 |

121 |

870 |

3350 |

90 |

45 |

25 |

250 |

105 |

130 |

175 |

20 |

96 |

125 |

5 |

40 |

|

1005 |

167 |

1200 |

2800 |

110 |

50 |

25 |

290 |

110 |

155 |

200 |

25 |

106 |

140 |

10 |

63 |

|

1006 |

258 |

1850 |

2500 |

125 |

65 |

25 |

320 |

125 |

175 |

230 |

25 |

125 |

150 |

10 |

86 |

|

1007 |

419 |

3000 |

2120 |

140 |

80 |

25 |

350 |

140 |

200 |

265 |

25 |

140 |

170 |

10 |

122 |

|

1008 |

524 |

3750 |

1900 |

160 |

95 |

25 |

390 |

160 |

235 |

300 |

28 |

152 |

190 |

10 |

160 |

|

1009 |

628 |

4500 |

1700 |

180 |

105 |

25 |

445 |

165 |

260 |

355 |

30 |

164 |

205 |

10 |

200 |

|

1010 |

1075 |

7700 |

1400 |

220 |

120 |

100 |

490 |

180 |

300 |

405 |

30 |

176 |

220 |

10 |

300 |

|

1011 |

1535 |

11000 |

1250 |

260 |

130 |

100 |

545 |

200 |

340 |

460 |

30 |

196 |

235 |

10 |

475 |

|

1012 |

2430 |

17400 |

1120 |

300 |

140 |

120 |

600 |

240 |

380 |

500 |

35 |

225 |

275 |

10 |

640 |

|

1013 |

3255 |

23300 |

1000 |

330 |

180 |

160 |

680 |

260 |

440 |

560 |

35 |

250 |

300 |

15 |

885 |

|

1014 |

4455 |

31900 |

900 |

355 |

230 |

210 |

730 |

280 |

480 |

610 |

35 |

270 |

320 |

15 |

1110 |

|

|

|||||||||||||||